Mobile robotics for good and parcel processing

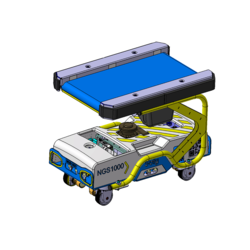

Soly™ is the SOLYSTIC’ solution based on a fleet of mobile robots managed in real time by an IT System which supervises all movements and permanently locates objects. Combined with trolleys, these robots individually transport objects placed on trays.

The benefits of the Soly™ solution

- No fixed infrastructure

- Flexible and scalable

- A collaborative work and a joint circulation with the operators

- Different trolleys to handle parcels, bags, bins and non-mechanizable loads

Soly™ Move

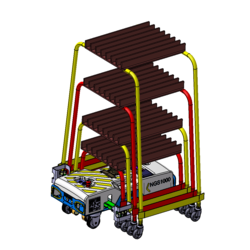

Soly™ Sort

Soly™ Sequencer

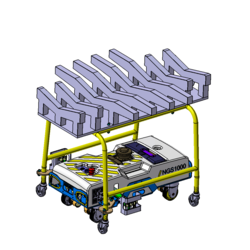

Soly™ Cart

Find the Live Tech Supply Chain dedicated to mobile robotics for intralogistics.

Application cases

- Soly™ Move: the handling of bags or irregular parcels in logistics operators' hubs,

- Soly™ Sort: the parcel sorting in bags, cartons and / or containers whose management is automated in the distribution centers,

- Soly™ Sequencer: the store delivery for retailers and the delivery preparation which discharge drivers of a tiring and time-consuming operation. They can be more efficiently to their delivery tour,

- Soly™ Cart: the moving of karts/rolling cages.

References

From now, more than 500 units have been sold.- France 2020: the DPD 'Big One' hub will be equipped with around fifty Soly™ robots and a robotic station for the replacement of batteries.

- France 2019: deployment of more than 40 Soly™ robots on a La Poste site, PIAC Roissy.

- France 2018: sorting of large parcels at Beaune on a DPD site.

- Italy 2018:

- small parcel sorting,

- transfer of full tanks from the XMS™ machine,

- handling of the containers around the TOP2000 machine,

- United States 2018: improved stock management thanks to the automated replenishment of the distribution centers'serving stores.

- United States 2017: optimization of the preparation of the parcels of a distribution leader for dispatch, before handing the parcels over to delivery operators.

- Asia 2017: test for sorting in bags, 11 robotic shuttles, 40 containers organized over less than 90 m².

- France 2016: round preparation application