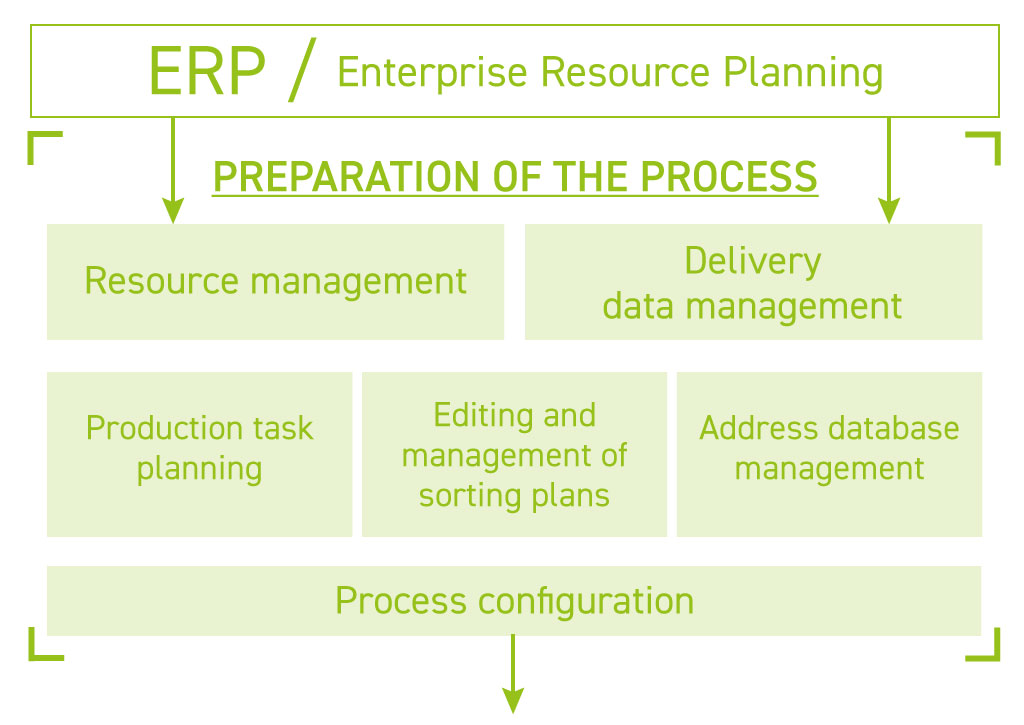

Preparation of the sorting process

Production task planning

The Simulation Planning Simulation Modeling (MSIP) solution, adapted to the industrial sorting process, allows site managers to create provisional schedules for the entire logistics network.

Are taken into account:

- the object flows to be processed,

- the entire equipment fleet,

- transmission and distribution constraints.

The SOLYSTIC solution simulates the operation of the network in advance of the phase and generates the skeletons of the sorting plans, intended for the editing tools.

Editing and management of sorting plans

SPMS (Sort Plan Management System) edits the sorting plans that are then executed on the machines. This system is based on:

- distribution data provided by customers,

- the tasks defined on each equipment,

- the intrinsic constraints of each sorting centre or warehouse.

Both the physical characteristics of the objects and the information they carry (addresses, bar codes) are used.

Management of address repositories

The repositories take into account the customers' distribution databases.

Production configuration management

This application manages the consistency of the configurations and provides them to the Warehouse Control System (WCS).